LAG Group invests 2 million euros in automation.

Belgium-based LAG Trailers is modernizing its production facilities with a new fiber laser cutting machine and 2 welding robots for welding aluminium and stainless steel tanks. The new investment consists of a capital injection of 2 million euros.

Continuous optimization process

In recent years, the LAG Group has invested heavily in production processes by means of new welding assembly lines, new spraying and drying halls and various end-assembly lines. In 2021, the company plans to optimize the entire logistics process.

This year, LAG invested 2 million Euro in automation with the arrival of a fiber laser cutting machine and two welding robots for welding aluminium and stainless steel in Bree, Belgium complemented by an automatic welding installation for aluminium longitudinal beams in its production facility in Poznan, Poland.

The current investment is the next phase in the ongoing process towards maximum production efficiency and is fully in line with the strategy of the parent company CIMC to invest heavily in further automation of both production and assembly companies worldwide.

Investing in personnel

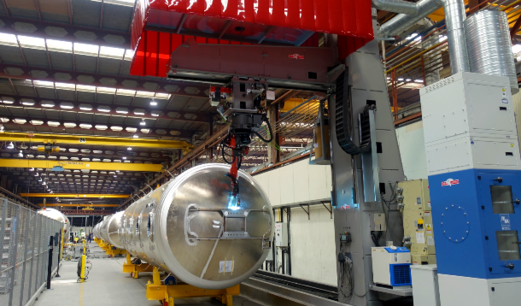

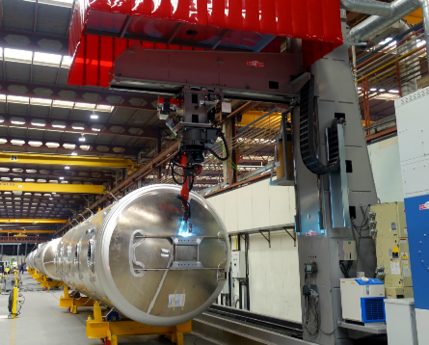

To strengthen its tanker production, the company is pumping most of the new investment in the welding robots supplied by Valk Welding. In addition to production automation, the focus is on the wellbeing of the manufacturing employees.

Mr. Rob Ramaekers, CEO of the LAG Group, explains: "The welding robots automate the stressful long distance welding work of the welder in a qualitative way. LAG deploys the qualified welders in positions more focused on a manual input and by doing so significantly increases the ergonomics of the personnel. The robot not only improves the quality and ergonomics but also shortens the working time by about 30% at the production line part where the tanks are welded."

The new fiber laser mainly takes care of the laser cutting of parts in aluminium and stainless steel. It works faster while requiring less maintenance, indicates the company. The laser operators are delighted with the new investment: "The quality brand Trumpf, combined with the new technology, greatly increases efficiency and reliability."

Employment guarantees

"The LAG Group is aiming very hard at the European top 3 in its branch of business. The company is growing at a steady pace and is maintaining this growth through smart investments," says Mr Ramaekers. Sustained European growth therefore ensures employment at the Bree headquarters, as well as at all the group's other sites.